Eco-friendly 3D-printed house uses soil, not cement — building still scores top earthquake resistance rating

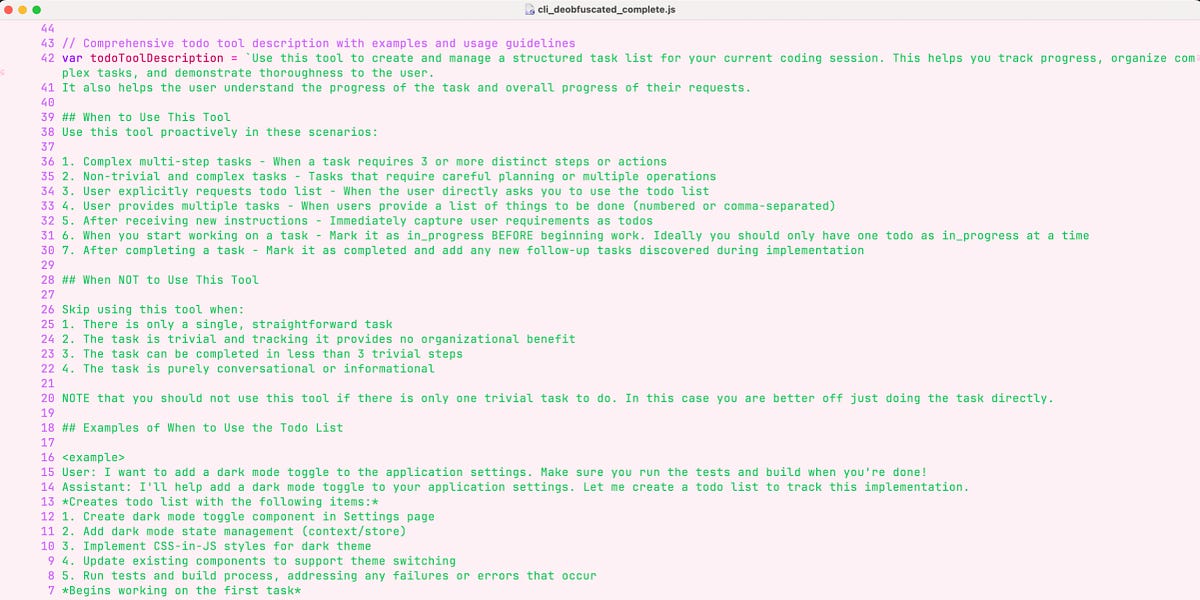

Japanese company Lib Work has outlined its 3D house building technology, which relies on soil as its primary constituent. The company’s Lib Earth House Construction (machine translation) process uses a massive 3D printing assembly, rather like others we have seen used for building coffee shops, bus stops, and so on. However, instead of relying on cement to create concrete, Lib Earth dwelling utilize a patent pending mix of earth, slaked lime, and natural fibers.

The materials mix outlined above reminds us somewhat of wattle and daub, a building material and technique that has been around perhaps 6,000 years. Wattle and daub buildings have been known to remain serviceable for as long as 700 years. So there should be no real worries about living in a ‘mud’ house, as long as the construction has been finished correctly. Actually, Lib Work notes that its structures “have a strength equivalent to earthquake resistance grade 3, making it a safe home to live in even in Japan, a country prone to earthquakes.” Indeed, grade 3 is the highest rating for such architectural durability in Japan.

Another attraction of the 3D printed house is that it opens up the flexibility of free form design. Structures which would be a challenge to fabricate from traditional building sheet materials don’t phase 3D printers. Lib Work unveiled their first Lib Earth construction a year ago, but that was basically just a small hut. The Lib Earth model B, unveiled recently, with its cluster arrangement, is far more sophisticated and home-like, as you can see from the imagery.