IoT Applications in Manufacturing Sector

With IoT applications in the manufacturing sector, manufacturers can monitor the condition of machinery and look for indicators predictive failure, for example – vibration, temperature or pressure outside threshold limits. This means that the technician needs to make fewer visits, reducing costs and resulting in faster recovery.

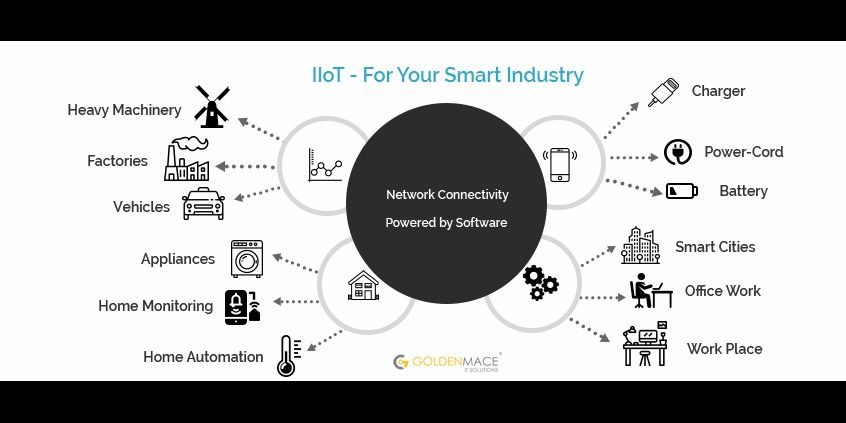

IIoT brings radical changes in the manufacturing process and can make the entire process flow and people more informed, efficient and productive. Smart manufacturing builds an environment where all information is available from within plant floor to supply chain.

By Connecting production line systems, manufacturers can move to predictive maintenance, making better use of resources and reducing unplanned downtime. It can improve equipment utilization and plant output overall. Manufacturers can also track pallets, shipping containers and equipment, both on and off site using location aware IoT devices. Using a mix of connectivity technologies, including cellular and satellite, this tracking can cover shipments across road, rail, sea and air transport.

This end-to-end monitoring reduces the chance of loss or theft and additional sensors can be used to verify that perishable or fragile goods are kept in appropriate conditions and handled properly throughout their journey.In connected supply chain, by connecting production line and plant equipment to suppliers, all units can understand inter-dependencies, the flow of materials and manufacturing cycle times.