A physical catalyst for the electrolysis of nitrogen to ammonia

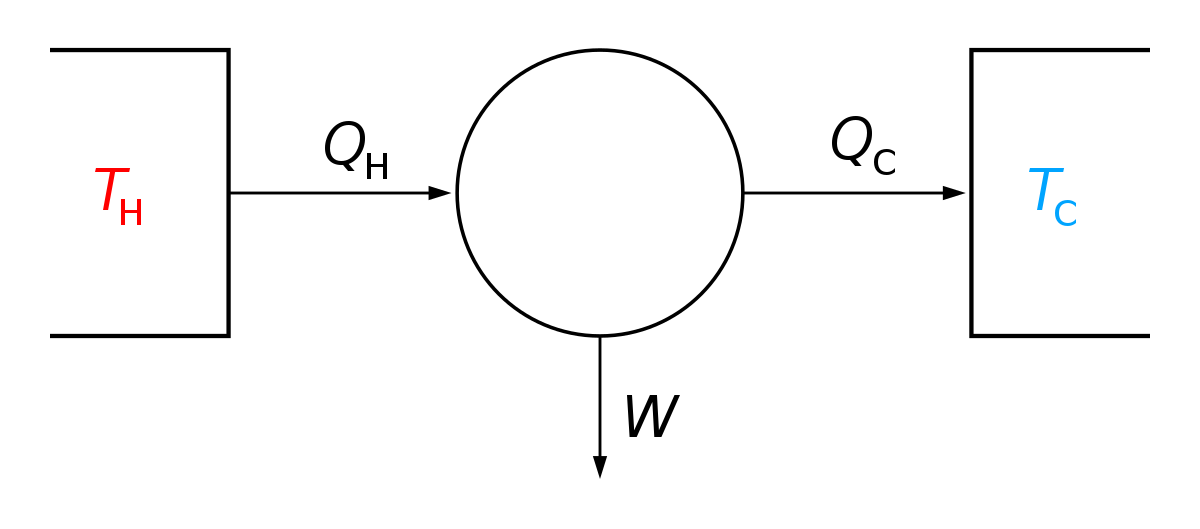

Ammonia synthesis consumes 3 to 5% of the world’s natural gas, making it a significant contributor to greenhouse gas emissions. Strategies for synthesizing ammonia that are not dependent on the energy-intensive and methane-based Haber-Bosch process are critically important for reducing global energy consumption and minimizing climate change. Motivated by a need to investigate novel nitrogen fixation mechanisms, we herein describe a highly textured physical catalyst, composed of N-doped carbon nanospikes, that electrochemically reduces dissolved N2 gas to ammonia in an aqueous electrolyte under ambient conditions. The Faradaic efficiency (FE) achieves 11.56 ± 0.85% at −1.19 V versus the reversible hydrogen electrode, and the maximum production rate is 97.18 ± 7.13 μg hour−1 cm−2. The catalyst contains no noble or rare metals but rather has a surface composed of sharp spikes, which concentrates the electric field at the tips, thereby promoting the electroreduction of dissolved N2 molecules near the electrode. The choice of electrolyte is also critically important because the reaction rate is dependent on the counterion type, suggesting a role in enhancing the electric field at the sharp spikes and increasing N2 concentration within the Stern layer. The energy efficiency of the reaction is estimated to be 5.25% at the current FE of 11.56%.

Worldwide production of ammonia exceeds 145 million metric tons annually (1). The Haber-Bosch process must be performed at high temperature and pressure using pure hydrogen, which is usually sourced from natural gas via steam reforming; hence, ammonia production represents a significant contributor to climate change. Because of this, alternative methods for synthesizing ammonia are now of great scientific interest (2–5). Although the literature is still sparse, a number of electrocatalytic studies that produce NH3 directly via electroreduction of N2 and water or steam have been reported (6). Most studies on electrochemical production of ammonia are based on solid-state electrolytes at elevated temperature and pressure (7). Other studies have also been reported on the basis of liquid electrolytes, such as organic solvents (8), ionic liquids (9), molten salts (10, 11), aqueous electrolyte at elevated (12) or ambient pressure (13), or fullerene electrodes with aqueous electrolyte (14). In these studies, transition metal complexes and materials are often exploited as the catalysts.