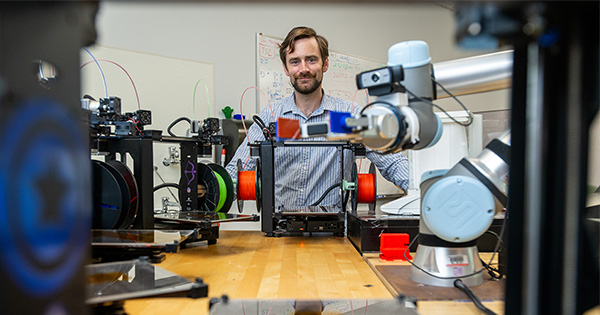

3D Printing Robot Uses AI Machine Learning for US Army Research

Inside a lab in Boston University’s College of Engineering, a robot arm drops small, plastic objects into a box placed perfectly on the floor to catch them as they fall. One by one, these tiny structures—feather-light, cylindrical pieces, no bigger than an inch tall—fill the box. Some are red, others blue, purple, green, or black.

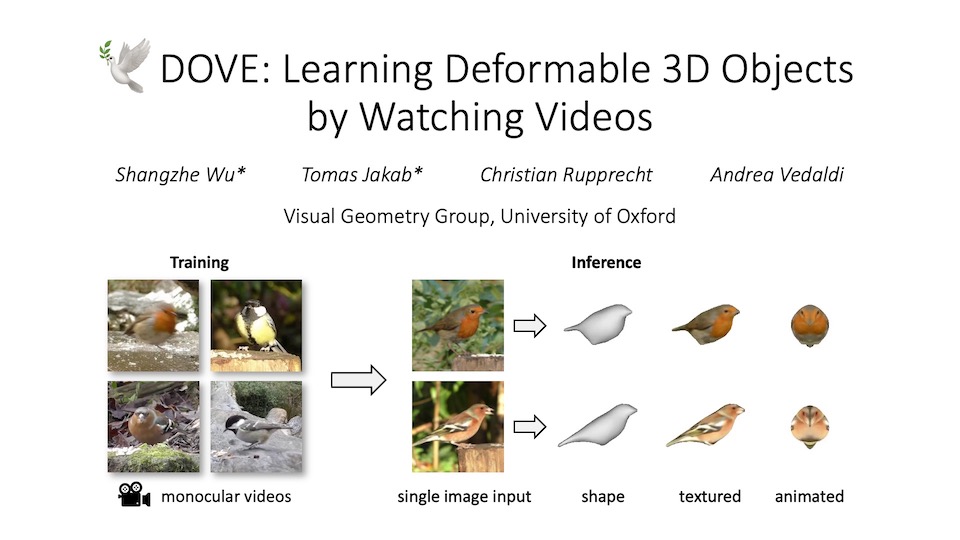

Each object is the result of an experiment in robot autonomy. On its own, learning as it goes, the robot is searching for, and trying to make, an object with the most efficient energy-absorbing shape to ever exist.

Watch the robot complete a full experiment, from printing a 3D shape, to crushing it under a metal plate, to dropping the discarded object in a box.

To do this, the robot creates a small plastic structure with a 3D printer, records its shape and size, moves it to a flat metal surface—and then crushes it with a pressure equivalent to an adult Arabian horse standing on a quarter. The robot then measures how much energy the structure absorbed, how its shape changed after being compressed, and records every detail in a vast database. Then, it drops the crushed object into the box and wipes the metal plate clean, ready to print and test the next piece. It will be ever-so-slightly different from its predecessor, its design and dimensions tweaked by the robot’s computer algorithm based on all past experiments—the basis of what’s called Bayesian optimization. Experiment after experiment, the 3D structures get better at absorbing the impact from getting crushed.

These experiments are possible because of the work of Keith Brown, an ENG associate professor of mechanical engineering, and his team in the KABlab. The robot, named MAMA BEAR—short for its lengthy full title, Mechanics of Additively Manufactured Architectures Bayesian Experimental Autonomous Researcher—has evolved since it was first conceptualized by Brown and his lab in 2018. By 2021, the lab had set the machine on its quest to make a shape that absorbs energy, a property known as its mechanical energy absorption efficiency. This current iteration has run continuously for over three years, filling dozens of boxes with more than 25,000 3D-printed structures.