BASF starts the World's First Electric Cracker Furnace

Electrifying steam cracking can reduce emissions in the chemical industry, but it does not change the use of fossil input materials. It is only a first step towards climate-neutral chemicals.

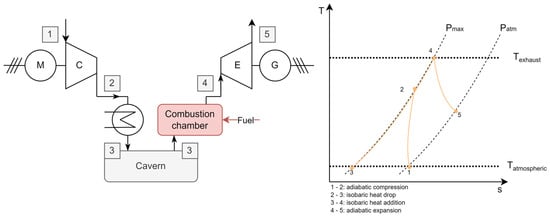

The chemical companies BASF, SABIC, and Linde have announced the startup of the world's first large-scale electric steam cracking furnace at BASF's site in Ludwigshafen, Germany. Steam crackers are amongst the most important and energy-intensive facilities in the chemical industry.

Steam crackers convert fossil input materials into basic building blocks of many products. In Europe, most steam crackers process naphtha made from oil. Elsewhere, using by-products from fossil gas drilling like ethane is also common. The most important output products of steam cracking are the olefins ethylene and propylene, which are the building blocks of most plastics.

The input materials in the cracker need to be heated to temperatures above 800 degrees Celsius (approximately 1,500 °F). Today, that heat is usually produced with fossil gas.