Using PCBs to create front panels for your projects | arx

Regular FR4 or aluminum PCBs can be used to create cheap (but beautiful) front panels for electronic projects. In this article, we'll explore various tips & techniques used to obtain the best results.

Example of an aluminum front panel. Black solder mask, white silkscreen (text), creamy dielectric on core (the frog) and silver HASL finish (the leaves).

It wouldn't be possible to compile these tips without reading through this massive thread on ModWiggler first. Huge thanks goes to everyone who contributed to the thread!

I personally use Kicad and JLCPCB to create my front panels. However, these tips are pretty universal and should apply to other CAD softwares and fab houses as well.

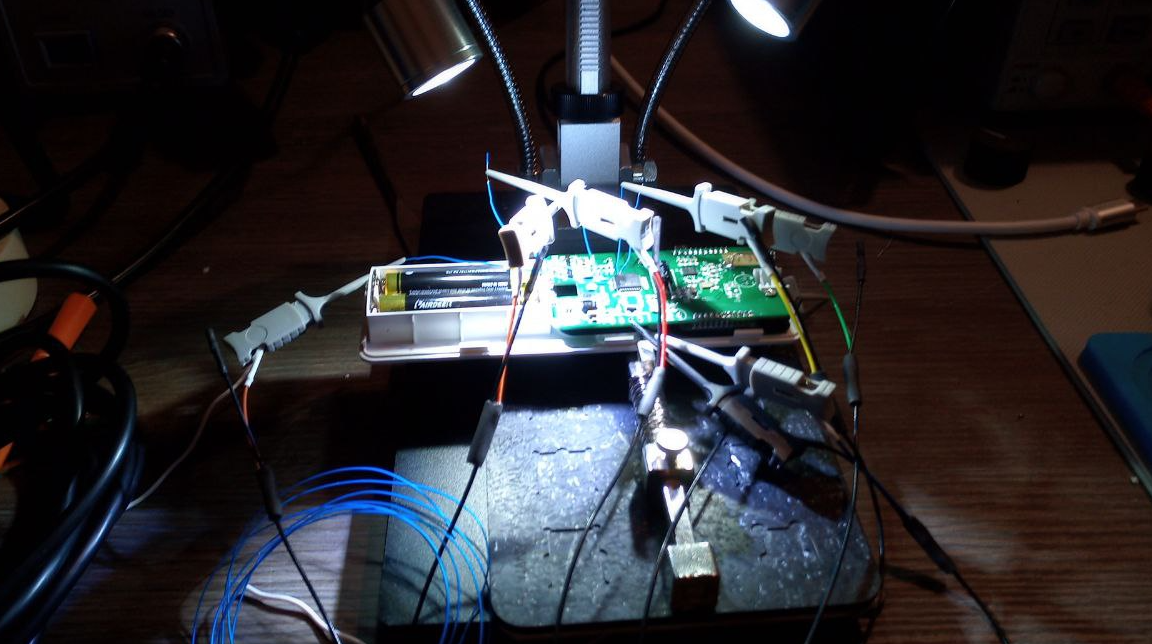

In order to test the capabilities of a fab house and demonstrate the points in this article, I created a PCB using various techniques. The bottom half of the board has the solder mask as the "background color" and shows the text and graphics on the silkscreen, on copper (HASL) and core. On the top half, the background is done by a continuous silkscreen fill, and the text and graphics are done on solder mask (an opening in silkscreen fill), copper and core.

Furthermore, the left half of the PCB has a solid copper fill; the right half has a cross-hatched copper fill. Smaller rectangular regions of different cross-hatch parameters (hatch width and gap) are present in the middle as well.